Electrohydrodynamic precision printing for fabrication of wearable sensor devices

Wearable, skin-like sensor devices embedded in stretchable substrate materials like thermoplastic polyurethane (TPU) have paved the way to manifold applications in the field of personalized health monitoring. They are accompanied by exceptional features such as a high durability, stretchability and a lightweight character. This opens up the detection of diverse physiological parameters and biomarkers.

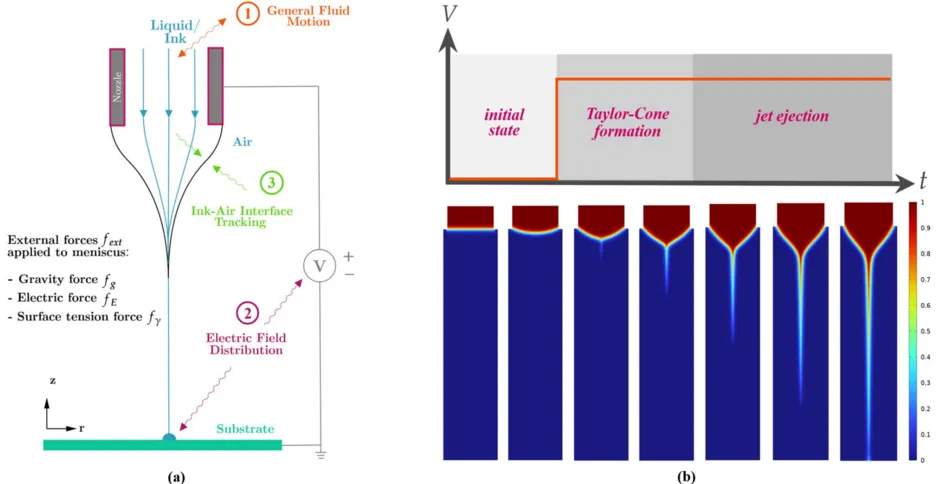

It results from the improvement of various additive techniques which overcome technological obstacles of established photolithographic approaches with respect to the overall process costs, the necessity of time-consuming fabrication steps within a cleanroom environment and, at the same time, enable a sustainable fabrication of flexible sensors and relating electronic components. To this end, the cutting-edge electrohydrodynamic (EHD) printing technology [1,2] for a precise patterning of microscaled wearable sensor structures is investigated in-depth within this project by finite-element-based simulations (cf. Figure 1).

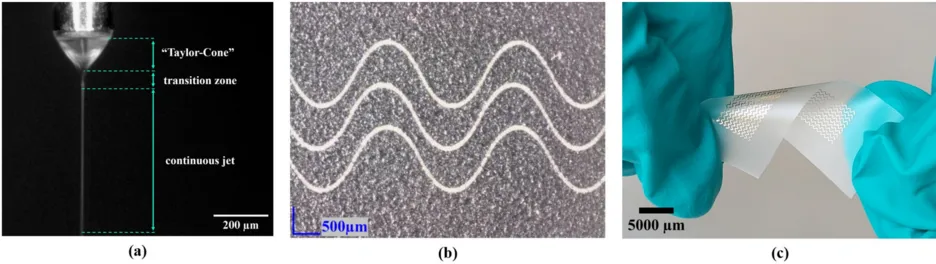

This extremely efficient printing approach is based on an electrohydrodynamically induced fluid flow through a capillary nozzle initiated by an appropriate electric field in the kV-range applied between the nozzle tip and the substrate. Moreover, this procedure leads the formation of the so-called "Taylor-Cone" and a filigree conejet with a diameter that is up to two orders of magnitude smaller than the inner nozzle diameter (cf. Figure 2 (a)). By utilizing a dielectric, conductive or biological medium, an accurate patterning of functional sensor structures is permitted. For a validation of the simulation results as well as for the fabrication of first demonstrators (Figure 2 (b) & (c)), an EHD printing system on laboratory scale is additionally developed.

The research project is carried out in cooperation with the Heilbronn University of Applied Sciences, represented by Prof. Dr.-Ing. Ingo Kuehne (Research Professor for Micro and Nanosystems), aiming the enhancement of EHD precision printing towards the fabrication of miniaturized sensor structures on hyperelastic, biocompatible TPU foils for a non-invasive diagnosis and prevention of multiple diseases.

References

[1] Philippin, N., Kuehne, I. & Schrag, G.: Conformable Electronics with Conductive Silver Structures by Electrohydrodynamic Printing. IEEE Journal on Flexible Electronics (J-FLEX), vol. 3, no. 7, pp. 348-355, 2024, doi:10.1109/JFLEX.2024.3420263.

[2] Philippin, N., Kuehne, I. & Schrag, G.: Electrohydrodynamic Printing of Conductive Microstrips on Hyperelastic Substrates for Fabrication of Flexible and Stretchable Sensors, In: IEEE International Conference on Flexible and Printable Sensors and Systems 2024 (IEEE FLEPS), Tampere, Finland, 2024, doi: 10.1109/FLEPS61194.2024.10603845