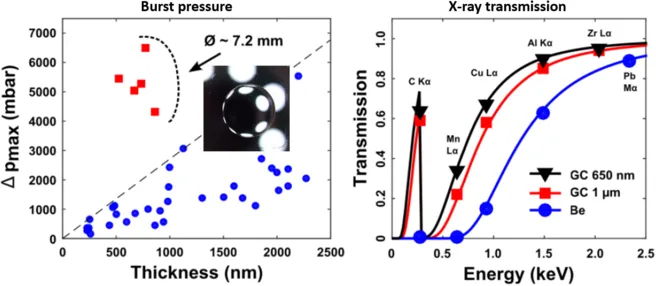

A newly developed 8 inch process improved performance for graphenic carbon membranes. A free-standing 650 nm thick membrane with 7.2 mm diameter has a burst pressure exceeding 6 bar. The new process delivers a carbon material that has a an ultimate tensil stress of ~ 7 GPa, which sets it on par with the strongest man-made fibers. And this value is averaged over an opening of 7.2 mm. A two-step process makes it now possible to make much thicker membranes, which would allow to substitute beryllium in much wider applications.

The peer-reviewed paper is published in MRS Advances by the Materials Research Society and Cambridge University press. A link to the paper is here and an open access version on the paper can be downloaded from researchgate or arxiv.org