We are happy to announce that the manuscript “Fully Integrated MEMS Micropump and Miniaturized Mass Flow Sensor as Basic Components for a Microdosing System”, authored by Dr. Martin Seidl and Prof. Dr. Gabriele Schrag, is now published in the Special Issue 'Selected Papers from 5th International Conference on Microfluidic Handling Systems' of MDPI Micromachines.

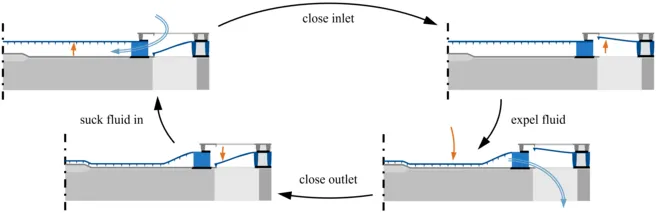

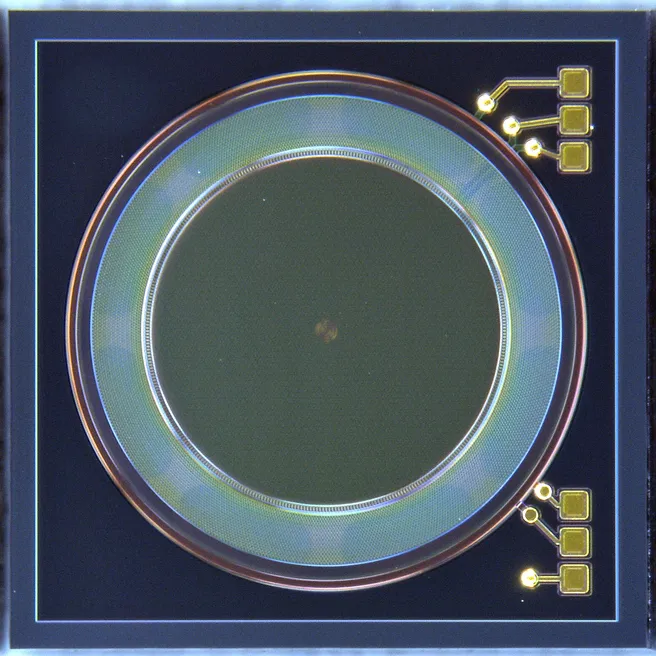

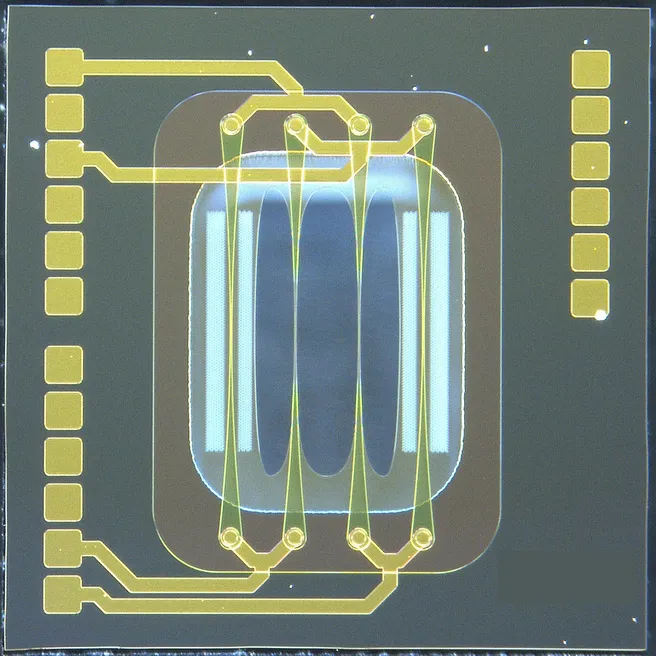

The paper presents a micropump concept and an associated mass flow sensor design, which, in combination, have the potential to form the basis for an integrated microfluidic development platform for microfluidic systems in general and microdosing systems in particular.

Available online: https://www.mdpi.com/2072-666X/15/12/1404, DOI: 10.3390/mi15121404